Johnson College hosted its annual Scholarship Breakfast on Wednesday, November 9, 2022, at Fiorelli Catering in Peckville. The event was held to recognize the scholarship recipients and thank and honor the generous donors who make scholarships available to students.

The College awarded 42 students with scholarships during the event. Devin Walsh, a student in Johnson College’s Heating, Ventilation & Air Conditioning program, and recipient of one of the College’s Presidential Scholarships served as student speaker.

“To me, the Presidential Scholarship is more than just money,” Walsh said. “It means that my accomplishments are valuable enough for Johnson to put such an enormous amount of faith in that I will follow through with my education and become a great example of what Johnson College provides to the community.”

Walsh says that the scholarship has lifted the burdens that accompany the cost of pursuing a degree in higher education.

“Most college students need to make major sacrifices, work numerous jobs, and take out huge loans that will cause stress, leading to the inability to focus on coursework,” Walsh told attendees. “The financial assistance of the Presidential Scholarship is a life changer for my family and me.”

The event also featured keynote speaker, David Hawk, who, with his wife Ann, are founders of the Hawk Family Foundation created to help the underprivileged, support education, and encourage community initiatives to help families thrive. The Hawk Family Foundation contributed to the College’s Innovation at Work Capital Campaign specifically for student scholarships and campus developments.

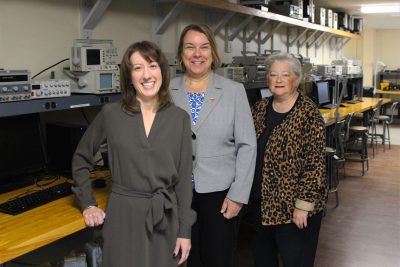

The breakfast concluded with the presentation of the scholarship awards by Katie Pittelli, Ed.D., president and CEO of Johnson College, and Jeanine Engelmann, Ed. D., Chief Academic Officer of Johnson College. The presented awards included:

AAA North Penn Annual Scholarship, Dylan DeGroat;

Andrew Mazza Memorial Scholarship, Gavin Noll;

Anthony Ploskonka Memorial Scholarship, Brianna Covington;

Bartolai Family Scholarship, Peter Winowich;

Christopher Pambianco ‘65 Book & Tool Scholarship, Kenneth Stucker;

C.M.C. Rich Vinansky Memorial Golf Tournament Scholarship, Jessica McKee;

Dr. George J. Hallesky Memorial Scholarship, Donovon Brown;

Ed Vogel Memorial Scholarship, Nicholas Lathrop;

Edgar A. and Ida M. Alekna Scholarship, Alexander Carpenetti, Luke Galli, Jordan Navarro, and Madison Trotto;

Frank and Jean Hubbard Scholarship, James Lamberti;

Hawk Family Foundation Scholarship, Julianne Feigenbutz and Christian Overholtz;

Irene Ploskonka Memorial Scholarship, Ryan Phillips;

Islyn Thomas Achievement Award, Alexander Canjar;

Janie Lamberton Memorial Scholarship, Cassidy Weber;

John K. and Mary E. Blackledge Memorial Scholarship, Andrea Marques;

John T. Gerod Scholarship, Richard Reed;

Johnson College Presidential Scholarship, Jessica McKee, Emily Ohme, and Devin Walsh;

The Margaret Briggs Foundation Scholarship, Matthew Spiccioli;

Moffat Merit Award, Richard Bowen;

Moses Taylor Foundation Scholarship, Sierra Matash, and Gina Simeone;

MotorWorld Lexus Scholarship, Jeremy Russo and Casey Williams;

Orlando S. Johnson Merit Award, Emma Faithfull and Madison Kier;

Ross Family Foundation Scholarship, Alyssa Crawford and Tiahna Jackson;

Ruth Stitt Morgan Memorial Scholarship, Kodee Bates;

Scranton UNICO Scholarship, Christopher Henderson;

Sean J. Calpin Automotive Technology Scholarship, Mackenzie Snyder;

Sebastian “Sebby” Amico Memorial Scholarship, Jallen Wilks;

Society of Broadcast Engineers, Chapter II Scholarship, Kyle Williams;

Technology Merit Award, Michael Altieri and Anna-Marie Lake;

The John R. O’Hara Scholarship, Brandon Grandinetti;

The P. Fricchione and Sons Scholarship, Jonathon Hunsberger;

Thomas Hesser Scholarship, Zachary Menichello;

and Villa Capri Cruisers Car Club Scholarship, Jeremy Russo.